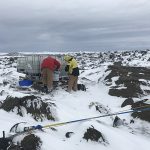

IG- Man-portable drilling

Our man-portable drill rigs are becoming increasingly popular with mineral explorers who are seeking access to difficult, rugged, or environmentally sensitive areas.

These small-scale single-barrel drill rigs do not generally replace larger and more complicated drill rigs (click here to see an example where man portable drill rig out-performs a conventional rig). However, they can help to reduce the cost of a drilling program by providing critical information on where to place a larger drill rig. They are also capable or providing a market reportable drilling result for a fraction of the cost of conventional drilling.

Man-portable drill rigs can consistently drill relatively quickly to depths of up to 20m. They require little or no ground preparation, and are quick to transport and fast to set-up. They are low cost and their low impact results in shortened work program approval times.

Independent Geologist has two man-portable drills and provides rigs and geologist on a daily rate basis. Couple a geologist with a drill rig and a hand-held XRF and you get reportable drilling results at low cost in almost real-time.

The following video shows the man-portable drill rigs in operation. It looks easy but, as with any drilling, success relies on choosing the right rods, bits and muds to support the task being undertaken.

Bauxite: The importance of the ratio of available alumina to reactive silica

Beware if you get presented with an analysis from a bauxite deposit and all it shows you is total alumina. Total alumina is important but, a bit like iron ore, it is not the whole story.

We seems to be doing more and more work assessing bauxite deposits.This reflects a change in the market away from commodities such as iron ore and carbon steel-related materials to their substitutes. This is not really surprising. The high prices for iron ore over recent years encouraged new supply, but also increased substitution. You guessed it. The effect is to compound downward price pressure once demand turned. We now see iron ore at levels not seen for a number of years, with futures for 62% CFR China indicating sustained depressed prices for some time to come.

Welcome to the world of bauxite, the raw material for aluminium. Substitution for steel (cars) and copper (conductors) has seen sustained demand and pricing for alumina. There is a shift in the exploration industry to acquiring new deposits with resources appearing in places not previously widely accepted as being economic. ABx Resources deposits in Tasmania might be a good example.

To an extent, alumina ores can be thought of in a similar way to iron ores. The DSO (Direct Shipping Ore) benchmark for iron is about 62% Fe. Higher grades can attract a premium price and lower grades a penalty. The same is true for alumina, although the benchmark grades tends to be lower for alumina at around 48%.

Like iron ore, it is the impurities that are often more important to consider than the head grade. I’ll talk about these impurities separately in another post. For this post, I’ll simply focus on this head grade figure. This is the larger number that is shown at the top of many assays. It is often the only number in older assays, and it can be misleading.

Not all alumina is available for making aluminium. Not all alumina that is available for making aluminium is of a type that you want to use in a factory to make aluminium. Confused?…..

The table below shows total alumina analyses for two samples. These are real examples. The total alumina in both samples is quite high. That’s good, right – NO! Only KTV01 is acceptable.

Firstly, analysis of the second sample (KTV02) shows a large proportion of the total alumina is contained in minerals where that alumina is not available to become aluminium product. The available alumina is low compared to the total alumina. This can happen, for example, where alumina in the rock is locked up in minerals that make it too expensive to extract – ie it is not available to the refinery and/ore smelter.

Secondly, a sample may contain unacceptably high levels of reactive silica. This is silica that reacts and consumes chemicals used in the Bayer process to extract aluminium. The consumption of these chemicals increases the cost of processing each ton of alumina.

As such, beware of older or incomplete assays which only show total alumina. A high total alumina is not always indicative of a good ore. A general rule is that you want the ratio of available alumina to reactive silica to be >10. You cant ignore total alumina, but if your ratios are right then an ore with total alumina as low as the mid-20%’s can be more profitable than one yielding a total alumina result in excess of 49%.

Of course, this is not the whole story. There are other factors to consider, but I’ll talk about these separately.

A scooter for (just about) every occasion….

I’m not a great one for cooking programs, but tonight’s Luke Nguyen’s cooking show caught my attention for talking about motor scooters in Vietnam. If you’ve travelled anywhere in Asia then you’ll know that these scooters are an important form of transport for individuals, families, freight, livestock and ….. ….yes, even trees.

One of the few times I was allowed to drive the scooter. Yes, that’s the owner on the back holding a very big bush knife.

Yes, I’ve come off more than once, commonly catapulted off the back after the driver fails to miss one of the (too) many potholes. Truth is, all credit to the driver for keeping me on the back and the bike upright in the first place. I’m not small. Add the driver, our packs, rock samples (iron ore!!!), rock hammers, food, water, and the odd (unsheathed) bush knife – no, not dangerous at all!

Many (…….hmmm…..ALL!….) of these little gems of moto-mayhem wouldn’t be roadworthy here in Australia. Missing foot pegs seem particularly common. No big deal you might say? Why pick out such a trivial problem others might point out? Ha, well, go try it for yourself and I guarantee you’ll experience ‘tender’!

Problems aside, these scooters go just about anywhere and do just about anything. I’ve traversed ground that would be impassable to a four wheel drive. I’ve closed my eyes and flown across decaying jungle bridges. I’ve even escaped illegal gold-miners riding a scooter at speed through the jungle (defimitely a story for another post)…….

Well done little scooter! You have proven yourself an indispensable addition to the exploration toolkit!!

Alistair Reed qualifies for Masters of Business

SRA is pleased to announced SRA employee and principal geologist Dr Alistair Reed has qualified for a Masters in Business from the University of Tasmania.

Says, Dr Reed “My studies in finance and corporations law have proven invaluable to me in my work with SRA. Understanding the business of mineral exploration is critical to marketing, developing and funding our exploration and mining projects.”

Dr Reed is expected to graduate in 2014.

Rod Campbell: A geologist in demand!

SRA are pleased to announce the addition of new staff member Rodrick (Rod) Campbell.

Rod comes to SRA with more than 5 years experience in iron ore and gold exploration with Tanami Gold and Pluton Resources, respectively. Says SRA director and partner, Dr Alistair Reed, “We are really lucky to have Rod working with us again. His experience really adds to SRA’s ability to conduct exploration in difficult areas.”

Rod’s employment is a result of SRA gaining funding out of Asia for exploration in southwestern Tasmania. Rod will also with SRA’s other projects in the United States and Asia.

Says Rod, “I’m really pleased to be back working with Tony and Alistair. We’ve worked well as a team in the past and I’m really looking forward to that again in the future.”

“SRA – All the way!”

Funding secured……

Schoer, Reed and Associates (SRA) are pleased to announce that they have secured funding for the next phase of gold exploration at Paragon Resources Elliott Bay gold project in southwestern Tasmania.

Schoer, Reed and Associates (SRA) are pleased to announce that they have secured funding for the next phase of gold exploration at Paragon Resources Elliott Bay gold project in southwestern Tasmania.

SRA manage the Elliott Bay gold project on behalf of Paragon Resources shareholders, coordinating exploration over an area of more than 100 square kilometers. This area includes highly prospective Mount Read Volcanic (MRV) rocks similar to those hosting world class mineral deposits at Rosebery (MMG) and Queenstown (Vedanta) to the north.

SRA partner and director, Dr Alistair Reed says, “We are very pleased to have been successful in raising private equity funding for this quality project at a time when many other companies in Australia are struggling to attract proper investment.”

Funding out of Asia will be used to develop and explore targets located along a newly discovered corridor of rocks referred to as the Discovery Creek Shear Zone (DCSZ). The DCSZ was discovered by SRA geologists following up on historic gold results. The DCSZ shares many characteristics with the Henty Fault in the northern MRV. Results to date are extremely positive, with visible gold in rock chips returning assay results of more than 5 ounces per tonne gold (160g/t Au). These results are of a preliminary nature only but are already more than 30 times the grade of gold ore being mined at Henty.