Man-portable drilling in Antarctica

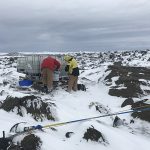

This version of our man-portable set-up uses and electric driver powered by a generator. This allows holes to be collared from inside a tent without risk from petrol fumes.

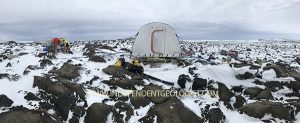

Mobile Weather Shelter (MWS) is set above the ground so that the base forms a working bench for drilling.

Water for drilling is provided from an IBC container. Drilling used about 700ltrs of water per day.

A generator is used to power the drill, avoiding the need to ventilate the tent of fumes.

A floor panel is removed providing access to the rock and collar location.

Collecting a geotechnical sample for laboratory testing.

Drill core recovered measures two sizes; about 75mm diameter and about 34mm diameter.

A mobile weather haven shelter is used as a base for drilling.

IG secures rights to sell man-portable core drills in Australasia

Cost-effective, value-for-money drilling solution for accessing remote, difficult or sensitive areas with minimal need for preparation and with minimal disturbance.

Man-portable drilling offers a cost-effective value-for-money solution to accessing remote, difficult or sensitive areas with minimal need for preparation and with minimal disturbance.

After using true man-portable core drills for a number of years, IG has now gone on to negotiate and secure the rights to sell the American-made machines in Australia and New Zealand.

Man-portable core drills offer a cost effective drilling solution that can help reduce need for larger more expensive drill rigs. They require little or no ground preparation and can get to locations not accessible to larger drill rigs. They are suitable for both geotechnical and mining/exploration-related work.

Core from man-portable drills is reportable to the stock exchange. Companies now have the ability to riase less cash on the back of early core drill results without the expense of larger scale drilling. Similarly, investors now have the ability to see funds directed to testing sites before funds are committed to larger rigs.

Our man-portable drills do not replace the need for larger drill rigs, but they can help reduce and focus use of these more expensive machines. Smaller machines can be used to quickly access a site to test where a larger machine might be best positioned. This can be done quickly with minimal or no ground preparation. This is critical in rugged, or culturally or environmentally sensitive areas.

IG will be progressively changing this website over coming weeks to provide additi0nal information on drilling products and techniques. In the interim, please contact us if you are interested in using our drilling services or in acquiring your own drills.

The following video shows the man-portable drill being used with a petrol driver. Both petrol and electric are available and their use depends on the location, the sort of drilling, ambient conditions and whether drilling is collared from within a confined space (such as from inside a tent, in the basement of a building or underground).

Man-portable core drills reach new heights

Drilling a highly foliated schistose rock on the side of a cliff in the Northern Territory.

Man-portable core drills are typically used in the early stages of exploration or for prospecting to identify sub-surface extensions of mineralisation. They are low cost alternatives to larger more expensive drills, requiring little or no regulatory approval for pads or tracks. This makes them quick, cheap and versatile.

Recent work in the Northern Territory desert for KGL Resources took the use of the man-portable drill to new heights: from exploration into the realms of Resource definition.

Infill drilling into known mineralisation can build up a level of confidence about the size and quality of the mineralisation to the point where it can be categorized as a ‘Resource’. But, what happens when a rugged topography prevents larger drill rigs accessing infill sites? The lack of infill information results in known mineralisation not being included in a Resource, underestimating both the size and value of that Resource. The value of that Resource underpins the value of the mineral asset. Thus, it’s non-inclusion negatively influences company value.

When that undrilled mineralisation is also located between the surface expressions of mineralisation and drilling at depth, then the ‘missing’ Resource is all the more valuable. This is because the mineralisation closest to surface is typically most accessible to mining, representing lower capital costs of development and earlier cash-flow to the company!

Man-portable core rigs typically do not replace larger rigs! A larger rig will get a larger, deeper sample more efficiently. However, they are more expensive to run, typically require access roads and prepared drill sites, which in turn may necessitate regulatory approval and the chance of increased bonds.

For KGL, the extra expense of using a larger drill rig was partially avoided by using Independent Geologist’s true man-portable drilling rigs. Each rig, complete with rods was mobilized by two people. No site preparation was necessary and separate approvals were not required. Hole depths were limited to less than 10m but could be spread in fences from cliff bottom to mid-cliff to cliff top. Hole positioning could be adjusted on the fly based on results at hand, with rig moves taking less than 1 hour.

Man-portable drills access confined spaces otherwise inaccessible to larger drills.

This drilling program requiring no separate approvals, no rehabilitation, no ground preparation and collared directly into mineralisation.

The end result? This low cost drilling program provided information on mineralisation with an in-ground value measured in the millions!

Click to read the KGL ASX release.

Another satisfied customer holder core produced using our man-portable drills.